Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

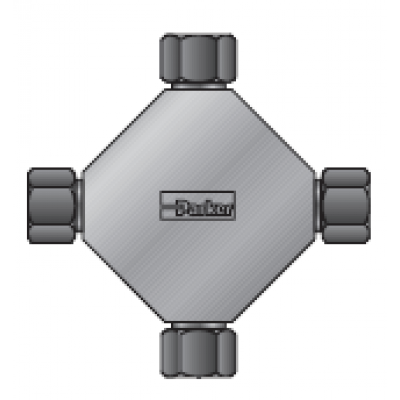

MPI Fittings

Tube Fitting, Inverted Two ferrule Compression - MPI Series

Parker's MPI™ Series is an

inverted two ferrule design engineered and manufactured to provide secure,

tight, and leak resistant connections for small bore instrumentation

applications up to 15,000 PSI.

Product Overview

Parker MPI™ Fittings are an inverted two ferrule,

compression design. They are engineered and manufactured to provide secure,

tight, and leak-resistant connections throughout industry, including off-shore

oil and gas exploration platforms, research labs, and other facilities that

require operating pressures in the range of 6,000 to 15,000 psi.

MPI™ Fittings are ideally suited to handle liquids, gases, or chemicals and can

be used on a wide variety of tubing materials including cold drawn – 1/8 hard

(unannealed) stainless steel tubing, annealed 2507 seamless tubing or

instrument grade thick-walled annealed stainless steel. Every Parker MPI™

Fitting is supplied complete and ready to install.

Markets:

• Offshore

• Oil and Gas

• Chemical

• Petrochemical

• Power

• Research

Features/Benefits:

• Front ferrule with corrosion-resistant Parker Suparcase® forms a seal between

the tube, body and ferrule. It also provides a mechanical hold on the tube.

• Back ferrule with corrosion-resistant Parker Suparcase® provides a strong

mechanical hold on the tube.

• Longer thread area for improved resistance to pressure and load on the

ferrules.

• Molybdenum disulfide-coated inverted nut helps prevent galling, provides

easier assembly, and permits multiple remakes.

• Long tube-support area improves resistance to vibration and line loads.

Applications:

• Offshore Process Panels

• Chemical Injection

• Well Head Control Panels

• High Pressure Tanks

Performance Characteristics

|

Fitting

Type |

Compression |

|

Materials of Construction |

Stainless Steel |

|

Connection 1 Size |

1/4"

to 3/4" |

|

Connection 2 Size |

1/4"

to 3/4" NPT M, NPT F, MPI

Compression |

|

Connection 3 Thread Size |

1/4

to 3/4 inch |

|

Connection 4 Thread Size |

1/4

to 3/4 inch |

|

Connection 3 Type |

MPI

Compression |

|

Connection 4 Type |

MPI

Compression |

|

Body Style |

Male Connector, Female Connector, Union, Elbow,

Tee, Cross |

|

Maximum Operating Pressure |

5,000, 10,000 psi |

Tube Fitting, Inverted Two ferrule Compression - MPI Series

Parker's MPI™ Series is an

inverted two ferrule design engineered and manufactured to provide secure,

tight, and leak resistant connections for small bore instrumentation

applications up to 15,000 PSI.

Product Overview

Parker MPI™ Fittings are an inverted two ferrule,

compression design. They are engineered and manufactured to provide secure,

tight, and leak-resistant connections throughout industry, including off-shore

oil and gas exploration platforms, research labs, and other facilities that

require operating pressures in the range of 6,000 to 15,000 psi.

MPI™ Fittings are ideally suited to handle liquids, gases, or chemicals and can

be used on a wide variety of tubing materials including cold drawn – 1/8 hard

(unannealed) stainless steel tubing, annealed 2507 seamless tubing or

instrument grade thick-walled annealed stainless steel. Every Parker MPI™

Fitting is supplied complete and ready to install.

Markets:

• Offshore

• Oil and Gas

• Chemical

• Petrochemical

• Power

• Research

Features/Benefits:

• Front ferrule with corrosion-resistant Parker Suparcase® forms a seal between

the tube, body and ferrule. It also provides a mechanical hold on the tube.

• Back ferrule with corrosion-resistant Parker Suparcase® provides a strong

mechanical hold on the tube.

• Longer thread area for improved resistance to pressure and load on the

ferrules.

• Molybdenum disulfide-coated inverted nut helps prevent galling, provides

easier assembly, and permits multiple remakes.

• Long tube-support area improves resistance to vibration and line loads.

Applications:

• Offshore Process Panels

• Chemical Injection

• Well Head Control Panels

• High Pressure Tanks

Performance Characteristics

|

Fitting

Type |

Compression |

|

Materials of Construction |

Stainless Steel |

|

Connection 1 Size |

1/4"

to 3/4" |

|

Connection 2 Size |

1/4"

to 3/4" NPT M, NPT F, MPI

Compression |

|

Connection 3 Thread Size |

1/4

to 3/4 inch |

|

Connection 4 Thread Size |

1/4

to 3/4 inch |

|

Connection 3 Type |

MPI

Compression |

|

Connection 4 Type |

MPI

Compression |

|

Body Style |

Male Connector, Female Connector, Union, Elbow,

Tee, Cross |

|

Maximum Operating Pressure |

5,000, 10,000 psi |