Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Phastite

Permanent Ferrule

Less Tube Fittings - Phastite® Series

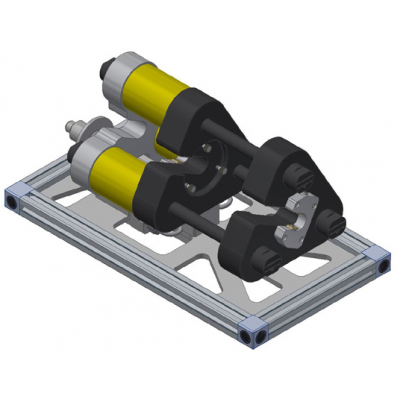

Parker's Phastite® permanent compression fitting offers an extremely quick, easy and simple way of permanently connecting tube. When considering how much time it takes to weld tubing, Phastite® delivers a huge reduction in total installation cost.

Product Overview

Phastite® is a breakthrough in tube connection

systems; its innovative design concept eliminates the costly requirement of

welding and combines quick installation with a signal assembly process

achieving a tube connector that can be used in applications up to 21,400

psi/1,470 bar. Developed in a range of standard and corrosion resistant alloys

to cope with the most demanding environments, from subsea exploration in the

north sea to natural gas drilling in Kazakhstan. Phastite® meets all the

relevant performance and functional requirements of industry standards.

Throughout the development of Phastite®, product performance and integrity were

paramount. A rigorous testing program including Thermal Cycling, Shock,

Vibration, Helium Leak, Gas Tight and Hydrostatic testing has been completed.

Markets:

•

Oil and Gas Offshore

•

Oil and Gas Onshore

•

Petrochemical

•

Chemical

Features/Benefits:

•

Reduced Installation Costs

•

Simple assembly process

•

No need to re-make or re-test

•

No welding required

•

Reduced tubing costs

•

Weight reduction

•

No loose parts

•

Simple make-up

•

Vibration tolerant

•

No need for hot work

Applications:

•

Instrumentation lines

•

Hydraulic power units

•

Chemical injection skids

Tech Specifications

|

Material Type |

Stainless Steel, Alloy 625, Alloy 825, Super Duplex |

|

Shape |

Straight, Elbow, Tee, Cross, Drop Size Straight, Termination

Male Straight, Termination Female Straight |

|

Fitting Style |

Tube to Tube, Tube to Pipe Thread |

|

Connection 1 Size |

1/4", 3/8", 1/2", 5/8", 3/4", 1",

6MM, 10MM, 12MM, 16MM, 20MM, 25MM |

|

Connection 2 Size |

1/4", 3/8", 1/2", 5/8", 3/4", 1",

6MM, 10MM, 12MM, 16MM, 20MM, 25MM, 8MM, 14MM, 18MM, 22MM, 1/4-18 NPT, 3/8-18

NPT, 1/2-14 NPT, 3/4-14 NPT, 1-11.5 NPT, 1/4-19 BSPP, 3/8-19 BSPP, 1/2-14

BSPP, 3/4-14 BSPP, 1-11.5 BSPP |

|

Specifications Met |

DNV Approved |

|

Connection Type |

Permanent , Termination |

|

Maximum Operating Pressure |

22,500 PSI 1,550 bar |

|

Industry Application |

Hydraulic Power Unit, Top Side Umbilical Termination Unit,

Remote Operated Vehicle, Semiconductor, Chemical Injection Skid |

|

Maximum Tube Outside Diameter |

25 mm 1" inch |

|

Assembly Time |

<2 Minutes |

|

Maximum Operating Temperature |

93°C 200°F |

|

Minimum Operating Temperature |

-45°C -50°F |

|

Fitting Type |

Tube-to-Tube Tube-to-Pipe-Thread Ferruless |

Permanent Ferrule

Less Tube Fittings - Phastite® Series

Parker's Phastite® permanent compression fitting offers an extremely quick, easy and simple way of permanently connecting tube. When considering how much time it takes to weld tubing, Phastite® delivers a huge reduction in total installation cost.

Product Overview

Phastite® is a breakthrough in tube connection

systems; its innovative design concept eliminates the costly requirement of

welding and combines quick installation with a signal assembly process

achieving a tube connector that can be used in applications up to 21,400

psi/1,470 bar. Developed in a range of standard and corrosion resistant alloys

to cope with the most demanding environments, from subsea exploration in the

north sea to natural gas drilling in Kazakhstan. Phastite® meets all the

relevant performance and functional requirements of industry standards.

Throughout the development of Phastite®, product performance and integrity were

paramount. A rigorous testing program including Thermal Cycling, Shock,

Vibration, Helium Leak, Gas Tight and Hydrostatic testing has been completed.

Markets:

•

Oil and Gas Offshore

•

Oil and Gas Onshore

•

Petrochemical

•

Chemical

Features/Benefits:

•

Reduced Installation Costs

•

Simple assembly process

•

No need to re-make or re-test

•

No welding required

•

Reduced tubing costs

•

Weight reduction

•

No loose parts

•

Simple make-up

•

Vibration tolerant

•

No need for hot work

Applications:

•

Instrumentation lines

•

Hydraulic power units

•

Chemical injection skids

Tech Specifications

|

Material Type |

Stainless Steel, Alloy 625, Alloy 825, Super Duplex |

|

Shape |

Straight, Elbow, Tee, Cross, Drop Size Straight, Termination

Male Straight, Termination Female Straight |

|

Fitting Style |

Tube to Tube, Tube to Pipe Thread |

|

Connection 1 Size |

1/4", 3/8", 1/2", 5/8", 3/4", 1",

6MM, 10MM, 12MM, 16MM, 20MM, 25MM |

|

Connection 2 Size |

1/4", 3/8", 1/2", 5/8", 3/4", 1",

6MM, 10MM, 12MM, 16MM, 20MM, 25MM, 8MM, 14MM, 18MM, 22MM, 1/4-18 NPT, 3/8-18

NPT, 1/2-14 NPT, 3/4-14 NPT, 1-11.5 NPT, 1/4-19 BSPP, 3/8-19 BSPP, 1/2-14

BSPP, 3/4-14 BSPP, 1-11.5 BSPP |

|

Specifications Met |

DNV Approved |

|

Connection Type |

Permanent , Termination |

|

Maximum Operating Pressure |

22,500 PSI 1,550 bar |

|

Industry Application |

Hydraulic Power Unit, Top Side Umbilical Termination Unit,

Remote Operated Vehicle, Semiconductor, Chemical Injection Skid |

|

Maximum Tube Outside Diameter |

25 mm 1" inch |

|

Assembly Time |

<2 Minutes |

|

Maximum Operating Temperature |

93°C 200°F |

|

Minimum Operating Temperature |

-45°C -50°F |

|

Fitting Type |

Tube-to-Tube Tube-to-Pipe-Thread Ferruless |