Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Rail Lubrication Systems

- Product Code: Rail Lubrication Systems

Rail

wear has been a challenge for many years in areas of tight curves or heavy

loaded tracks. Additionally, in dry weather, the so-called curve screeching or

squealing can occur.

Thousands

of trains around the world operate more reliably and efficiently because of SKF

and Lincoln automatic lubrication systems. By delivering precise amounts of

lubricant directly to the wheel/rail interface, automatic lubrication systems

provide significant benefits in terms of wear, energy and noise reduction.

SKF Easy Rail

Systems

SKF EasyRail systems

for wheel flange lubrication and railhead conditioning are mounted on-board on

the first leading vehicle axle. These systems require low maintenance and operate reliable even

under extreme climate conditions.

·

Maintenance-optimized system configuration

·

Longer intervals between wheel reshaping or replacement

·

Reduced vehicle downtime

·

Lower noise emissions

·

Reduced energy and material consumption

·

Use of biodegradable lubricants

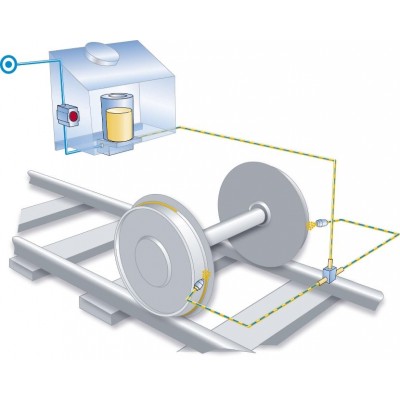

Way Side

Lubrication Systems

Wayside

lubrication systems effectively apply a consistent and controlled volume of

lubricant to the rail and hold that grease or friction modifier in place,

allowing the wheels to grab and carry it around the track curve. The product

range includes solutions for gauge face, top-of-rail and restraining rail.

In wayside lubrication systems passing

trains are detected by track-mounted wheel sensors. The applied lubricant is

picked up by passing wheels, which carry the lubricant through the up-coming

curve(s).

The systems

are capable of pumping long distances, as well as high-viscosity lubricants.

Dual-track systems and customized solutions are available.

Wayside

lubrication systems deliver small, measured amounts of lubricant precisely when

needed, when the train is passing. This approach increases system reliability and reduces lubricant consumption.

·

Maintenance-optimized system configuration

·

Lower noise emissions

·

“No-clog” lubrication via high-pressure pumps

·

Exact metering of grease

·

Cost-effective, combined gauge face and top-of-rail system layouts

possible.

Rail

wear has been a challenge for many years in areas of tight curves or heavy

loaded tracks. Additionally, in dry weather, the so-called curve screeching or

squealing can occur.

Thousands

of trains around the world operate more reliably and efficiently because of SKF

and Lincoln automatic lubrication systems. By delivering precise amounts of

lubricant directly to the wheel/rail interface, automatic lubrication systems

provide significant benefits in terms of wear, energy and noise reduction.

SKF Easy Rail

Systems

SKF EasyRail systems

for wheel flange lubrication and railhead conditioning are mounted on-board on

the first leading vehicle axle. These systems require low maintenance and operate reliable even

under extreme climate conditions.

·

Maintenance-optimized system configuration

·

Longer intervals between wheel reshaping or replacement

·

Reduced vehicle downtime

·

Lower noise emissions

·

Reduced energy and material consumption

·

Use of biodegradable lubricants

Way Side

Lubrication Systems

Wayside

lubrication systems effectively apply a consistent and controlled volume of

lubricant to the rail and hold that grease or friction modifier in place,

allowing the wheels to grab and carry it around the track curve. The product

range includes solutions for gauge face, top-of-rail and restraining rail.

In wayside lubrication systems passing

trains are detected by track-mounted wheel sensors. The applied lubricant is

picked up by passing wheels, which carry the lubricant through the up-coming

curve(s).

The systems

are capable of pumping long distances, as well as high-viscosity lubricants.

Dual-track systems and customized solutions are available.

Wayside

lubrication systems deliver small, measured amounts of lubricant precisely when

needed, when the train is passing. This approach increases system reliability and reduces lubricant consumption.

·

Maintenance-optimized system configuration

·

Lower noise emissions

·

“No-clog” lubrication via high-pressure pumps

·

Exact metering of grease

·

Cost-effective, combined gauge face and top-of-rail system layouts

possible.