Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

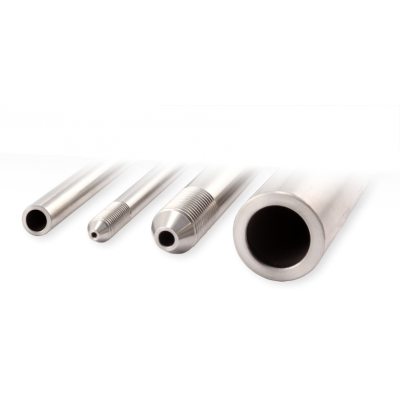

Tubes for Sour Service

Tubing, Autoclave

Series - 30,000 PSI Sour Gas Service

Parker Autoclave's high pressure Sour Gas Service (SOG) tubing is capable of operating to 30,000 psi (2068 bar) and range in size from 1/4" to 9/16" tube size. Tubing is manufactured from annealed stainless steel.

Parker Autoclave's high pressure

tubing designed for use with Parker Autoclave’s Sour Gas Service (SOG) fittings

and valves. This SOG package of components is rated up to 30,000 PSI (2068

BAR). The high-pressure tubing is used as fluid handling components in oil and

gas industries where H2S is present. This tubing is available in various sizes

and pressure ratings for optimal performance. In addition, the SOG components

are available with standard API Test and gauge connections (Autoclave

F562C).

Markets:

• Oil and Gas

(H2S)

• Petrochemical

• Chemical

Features/Benefits:

• Working

pressures to 30,000 psi (2068 bar)

• Designed for

Parker Autoclave Cone and Thread connection

• Tubing sizes

are 1/4", 3/8", and 9/16"

• Tubing is

manufactured from annealed 316 stainless steel

• Operating

temperatures from -423ºF (-252ºC ) to 1200ºF (649ºC)

• Stock tubing

lengths from 20 to 27 foot (6 to 8.2 meters)

Applications:

• High Pressure

Test Panels

• Fluid handling

Systems for H2S (Sour Gas)

• Chemical

Injection

• High Pressure

Gas Systems

|

Assembly |

Special Tool Required |

|

Pressure

Rating |

30,000 psi, 2068.39 bar |

|

Application |

Hydraulic,

Instrumentation, Media Transfer, Suction / Vacuum |

|

Specifications

Met |

ASTM,

ISO |

|

Materials

of Construction |

6Mo,

904L, Alloy 625, Alloy 825, Alloy C-276, Duplex, Monel, Other Stainless

Steel, Stainless Steel, Super Duplex, Titanium, 316 Stainless Steel |

|

Maximum

Operating Pressure |

34

(and over) bar, up to 1,550 bar, up to 34 bar, up to 7 bar, 500 and over psi,

up to 100 psi, up to 22,500 psi, up to 500 psi |

|

Maximum

Operating Temperature |

240

and over °C, up to 100 °C, up to 125 °C, up to 150 °C, up to 240 °C, up to

650 °C, up to 1200 °F, up to 212 °F, up to 257 °F, up to 302 °F, up to 464 °F

|

|

Media |

Abrasives,

Adhesives / Glue, Chemical Fluids, Food & Beverages, Fuels, Gases, H2S,

Hydraulic Fluids, Medical Fluids, Oil / Petroleum, Pharmaceutical Fluids,

Pneumatic Media, Steam, Water |

|

Minimum

Operating Temperature |

0

(and up) °C, 10 and up °C, -40 and up °C, -50 and up °C, -70 and up °C, 32

and up °F, -40 and up °F, 50 and up °F, -58 and up °F, -94 and up °F |

|

Outside

Diameter |

1/2

to 3/4 inch, 1/4 to 1/2 inch |

|

Tube

Wall Thickness |

0.083,

0.125, 0.187 inch, 2.11 , 3.18 , 4.75 mm |

|

Flow

Area |

0.005,

0.012, 0.028 inch2, 3.23 mm², 7.74 mm², 18.06 mm² inch2 |

FAILURE OR IMPROPER

SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN

CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. This document and other

information from Parker-Hannifin Corporation, its subsidiaries and authorized

distributors provide product or system options for further investigation by

users having technical expertise. The user, through its own analysis and

testing, is solely responsible for making the final selection of the system and

components and assuring that all performance, endurance, maintenance, safety

and warning requirements of the application are met. The user must analyze all

aspects of the application, follow applicable industry standards, and follow

the information concerning the product in the current product catalog and in

any other materials provided from Parker or its subsidiaries or authorized

distributors. To the extent that Parker or its subsidiaries or authorized

distributors provide component or system options based upon data or

specifications provided by the user, the user is responsible for determining

that such data and specifications are suitable and sufficient for all

applications and reasonably foreseeable uses of the components or systems.

Tubing, Autoclave

Series - 30,000 PSI Sour Gas Service

Parker Autoclave's high pressure Sour Gas Service (SOG) tubing is capable of operating to 30,000 psi (2068 bar) and range in size from 1/4" to 9/16" tube size. Tubing is manufactured from annealed stainless steel.

Parker Autoclave's high pressure

tubing designed for use with Parker Autoclave’s Sour Gas Service (SOG) fittings

and valves. This SOG package of components is rated up to 30,000 PSI (2068

BAR). The high-pressure tubing is used as fluid handling components in oil and

gas industries where H2S is present. This tubing is available in various sizes

and pressure ratings for optimal performance. In addition, the SOG components

are available with standard API Test and gauge connections (Autoclave

F562C).

Markets:

• Oil and Gas

(H2S)

• Petrochemical

• Chemical

Features/Benefits:

• Working

pressures to 30,000 psi (2068 bar)

• Designed for

Parker Autoclave Cone and Thread connection

• Tubing sizes

are 1/4", 3/8", and 9/16"

• Tubing is

manufactured from annealed 316 stainless steel

• Operating

temperatures from -423ºF (-252ºC ) to 1200ºF (649ºC)

• Stock tubing

lengths from 20 to 27 foot (6 to 8.2 meters)

Applications:

• High Pressure

Test Panels

• Fluid handling

Systems for H2S (Sour Gas)

• Chemical

Injection

• High Pressure

Gas Systems

|

Assembly |

Special Tool Required |

|

Pressure

Rating |

30,000 psi, 2068.39 bar |

|

Application |

Hydraulic,

Instrumentation, Media Transfer, Suction / Vacuum |

|

Specifications

Met |

ASTM,

ISO |

|

Materials

of Construction |

6Mo,

904L, Alloy 625, Alloy 825, Alloy C-276, Duplex, Monel, Other Stainless

Steel, Stainless Steel, Super Duplex, Titanium, 316 Stainless Steel |

|

Maximum

Operating Pressure |

34

(and over) bar, up to 1,550 bar, up to 34 bar, up to 7 bar, 500 and over psi,

up to 100 psi, up to 22,500 psi, up to 500 psi |

|

Maximum

Operating Temperature |

240

and over °C, up to 100 °C, up to 125 °C, up to 150 °C, up to 240 °C, up to

650 °C, up to 1200 °F, up to 212 °F, up to 257 °F, up to 302 °F, up to 464 °F

|

|

Media |

Abrasives,

Adhesives / Glue, Chemical Fluids, Food & Beverages, Fuels, Gases, H2S,

Hydraulic Fluids, Medical Fluids, Oil / Petroleum, Pharmaceutical Fluids,

Pneumatic Media, Steam, Water |

|

Minimum

Operating Temperature |

0

(and up) °C, 10 and up °C, -40 and up °C, -50 and up °C, -70 and up °C, 32

and up °F, -40 and up °F, 50 and up °F, -58 and up °F, -94 and up °F |

|

Outside

Diameter |

1/2

to 3/4 inch, 1/4 to 1/2 inch |

|

Tube

Wall Thickness |

0.083,

0.125, 0.187 inch, 2.11 , 3.18 , 4.75 mm |

|

Flow

Area |

0.005,

0.012, 0.028 inch2, 3.23 mm², 7.74 mm², 18.06 mm² inch2 |

FAILURE OR IMPROPER

SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN

CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. This document and other

information from Parker-Hannifin Corporation, its subsidiaries and authorized

distributors provide product or system options for further investigation by

users having technical expertise. The user, through its own analysis and

testing, is solely responsible for making the final selection of the system and

components and assuring that all performance, endurance, maintenance, safety

and warning requirements of the application are met. The user must analyze all

aspects of the application, follow applicable industry standards, and follow

the information concerning the product in the current product catalog and in

any other materials provided from Parker or its subsidiaries or authorized

distributors. To the extent that Parker or its subsidiaries or authorized

distributors provide component or system options based upon data or

specifications provided by the user, the user is responsible for determining

that such data and specifications are suitable and sufficient for all

applications and reasonably foreseeable uses of the components or systems.