Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Needle Valves

Needle Valve

Needle Valve, Pipe Valve P Series - 15,000 PSI

Parker Autoclave's P

Series needle valves offer a diverse line of pipe valves for small bore

instrumentation applications in the oil and gas processing industry. These are

rated to 15,000 psi (1034 bar) with sizes ranging from 1/4" to 1"

pipe. Parker Autoclave's P Series pipe

needle valves are designed to provide a commercial easy to use connection for

gas and liquid service. These valves are complemented by a complete line of fittings,

tubing and accessories. P Series valve design provides in-line pipe connections

for 1/4” to 1” pipe sizes. These pipe valves work in pressures up to 15,000 psi

(1034 bar). Operating temperatures can go from -423F to 400°F (-252°C to 204°C)

with 316 stainless steel body as standard.

Needle Valves, SW Series - 15,000 PSI

Parker Autoclave's SW Series needle valves are designed as a high flow, non-rotating rising stem valve, with working pressures to 15,000 psi (1034 bar). The Parker Autoclave tubing sizes range from 1/8"" to 1/2"". Tubing connections utilizes Parker Autoclave Speed Bite single ferrule design. Operating temperatures from 0°F to 650°F (-17.8°C to 343°C). 316 stainless steel construction, other options available. Along with their many features these valves provide dependable and trouble free service in wide variety of applications.

Needle Valve - Medium Pressure Cone & Thread

20,000 psi (1380 bar)

15SM and 20SM Series

SM Series Valves are

designed specifically for use with matching orifice Medium Pressure Cone &

Thread Fittings and Tubing for the most efficient flow path possible using Cone

& Thread style connections. Designed for a maximum of 20,000 psi MAWP using

high tensile strength UNS S31600/S31603 cold worked 316/316L Stainless Steel

material as standard, we include larger ID tubing rated to 15,000 psi (15SM

valves) for even higher flow rate capability.

15SM Series valves

available in sizes from 9/16" to 1-1/2" (See matching tubing)

20SM Series valves

available in sizes from 1/4" to 1" (See matching tubing)

Needle Valve - High Pressure Cone & Thread

60,000 psi, 100,000 psi, 150,000 psi

30SC, 43SC, 30VM, 40VM, 60VM, 100VM, and 150V Series

High Pressure Valve (to 60,000 psi)

Features:

•Temperature Rated -423° to 1200°F (-252° to 650°C) with options

•Manufactured with UNS S31600/S31603 cold worked 316/316L

stainless steel made to PAE proprietary standard

•Various designs cover valve sizes 1/4" to 1” that use the

“F” Series Connections (see Tools & Installation)

•Non-Rotating stem prevents stem/seat galling

•Metal-to-metal seating achieves bubble-tight shut-off, longer

stem/seat life in abrasive flow, greater durability for repeated on/off cycles

and excellent corrosion resistance

•For dependable stem and body sealing 30SC, 43SC, and 30VM valves

are furnished with PTFE packing; the 40VM and 60VM valves feature

nylon/leather/nylon packing below threads and all can be used on liquids and

gases

•Choice of Vee (Shutoff) or Regulating (Flow Control) stem tips

available with optional N-Dura or Stellite material options for severe service

Series 100VM: Pressures to 100,000 psi

(6900 bar) features:

•Cold-worked type 316 or 15-5PH stainless steel body with aluminum

bronze packing gland and on-rotating stem

•Nylon/leather/nylon packing below stem threads

•Sizes from 1/4" to 9/16" that use the “F***C100” Series

Connections (see Tools & Installation)

Series 150V: Pressures to 150,000 psi (10340 bar) features:

•Cylindrical body of high strength 15-5PH stainless steel with

aluminum bronze packing gland. Tool steel non-rotating stem with replaceable

seat of nickel maraging steel. Stem must be actuated with torque wrench see

page 22 for torque values

•Wedge-type PTFE and leather packing below stem threads with

beryllium-copper Parker Autoclave Anti-Extrusion Back up Rings

•Designed for use with 5/16" 150 Ksi tubing only, Vee stem

tip (Shutoff) only

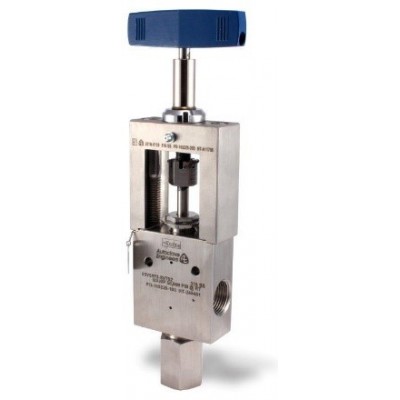

Needle Valve, Yoke Style - Y Series 50,000 PSI

Parker Autoclave's Y Series yoke valves are a non-rotating rising stem design, working pressures to 50,000 psi (3447 bar). These yoke valves are extra heavy duty, plant grade instrument valves for industrial and severe service applications. Yoke valves feature low closing torque for ease of operation. The tubing size is 9/16” to 1”. Tubing connections utilize the Parker Autoclave cone and thread design. Standard high pressure needle valves with PTFE packing may be operated from 0°F (-17.8°C) to 450°F (232°C). High temperature packing is available for service 600°F (316°C). These high pressure needle valves have adjustable packing below the threads to eliminate the media from contacting the power threads, and causing galling during actuation.

Along with

their many features these valves provide dependable and trouble free service in

wide variety of applications.

Needle Valve, Diverter 20DV Series - 20,000 PSI

Parker Autoclave's 20DV Series diverter needle valves

are designed with a non-rotating rising stem valve, with working pressures to

20,000 psi (1379 bar). This diverter valve uses the Parker Autoclave tubing in

sizes ranging from 9/16"" to 1"". Diverter valves provide

the ability to direct incoming flow to one of two outlets. Flow is changed by rotating

the handle in or out causing a double-ended stem to block the flow path to the

outlet not needed.

Diverter valves eliminate the need for multiple valves

and the possibility of error in flow direction changes. The 20DV series uses

Parker Autoclave Engineers' medium pressure connection. This coned and threaded

connection provides a reliable bubble-tight seal for dependable performance in

a variety of applications.

Needle Valve

Needle Valve, Pipe Valve P Series - 15,000 PSI

Parker Autoclave's P

Series needle valves offer a diverse line of pipe valves for small bore

instrumentation applications in the oil and gas processing industry. These are

rated to 15,000 psi (1034 bar) with sizes ranging from 1/4" to 1"

pipe. Parker Autoclave's P Series pipe

needle valves are designed to provide a commercial easy to use connection for

gas and liquid service. These valves are complemented by a complete line of fittings,

tubing and accessories. P Series valve design provides in-line pipe connections

for 1/4” to 1” pipe sizes. These pipe valves work in pressures up to 15,000 psi

(1034 bar). Operating temperatures can go from -423F to 400°F (-252°C to 204°C)

with 316 stainless steel body as standard.

Needle Valves, SW Series - 15,000 PSI

Parker Autoclave's SW Series needle valves are designed as a high flow, non-rotating rising stem valve, with working pressures to 15,000 psi (1034 bar). The Parker Autoclave tubing sizes range from 1/8"" to 1/2"". Tubing connections utilizes Parker Autoclave Speed Bite single ferrule design. Operating temperatures from 0°F to 650°F (-17.8°C to 343°C). 316 stainless steel construction, other options available. Along with their many features these valves provide dependable and trouble free service in wide variety of applications.

Needle Valve - Medium Pressure Cone & Thread

20,000 psi (1380 bar)

15SM and 20SM Series

SM Series Valves are

designed specifically for use with matching orifice Medium Pressure Cone &

Thread Fittings and Tubing for the most efficient flow path possible using Cone

& Thread style connections. Designed for a maximum of 20,000 psi MAWP using

high tensile strength UNS S31600/S31603 cold worked 316/316L Stainless Steel

material as standard, we include larger ID tubing rated to 15,000 psi (15SM

valves) for even higher flow rate capability.

15SM Series valves

available in sizes from 9/16" to 1-1/2" (See matching tubing)

20SM Series valves

available in sizes from 1/4" to 1" (See matching tubing)

Needle Valve - High Pressure Cone & Thread

60,000 psi, 100,000 psi, 150,000 psi

30SC, 43SC, 30VM, 40VM, 60VM, 100VM, and 150V Series

High Pressure Valve (to 60,000 psi)

Features:

•Temperature Rated -423° to 1200°F (-252° to 650°C) with options

•Manufactured with UNS S31600/S31603 cold worked 316/316L

stainless steel made to PAE proprietary standard

•Various designs cover valve sizes 1/4" to 1” that use the

“F” Series Connections (see Tools & Installation)

•Non-Rotating stem prevents stem/seat galling

•Metal-to-metal seating achieves bubble-tight shut-off, longer

stem/seat life in abrasive flow, greater durability for repeated on/off cycles

and excellent corrosion resistance

•For dependable stem and body sealing 30SC, 43SC, and 30VM valves

are furnished with PTFE packing; the 40VM and 60VM valves feature

nylon/leather/nylon packing below threads and all can be used on liquids and

gases

•Choice of Vee (Shutoff) or Regulating (Flow Control) stem tips

available with optional N-Dura or Stellite material options for severe service

Series 100VM: Pressures to 100,000 psi

(6900 bar) features:

•Cold-worked type 316 or 15-5PH stainless steel body with aluminum

bronze packing gland and on-rotating stem

•Nylon/leather/nylon packing below stem threads

•Sizes from 1/4" to 9/16" that use the “F***C100” Series

Connections (see Tools & Installation)

Series 150V: Pressures to 150,000 psi (10340 bar) features:

•Cylindrical body of high strength 15-5PH stainless steel with

aluminum bronze packing gland. Tool steel non-rotating stem with replaceable

seat of nickel maraging steel. Stem must be actuated with torque wrench see

page 22 for torque values

•Wedge-type PTFE and leather packing below stem threads with

beryllium-copper Parker Autoclave Anti-Extrusion Back up Rings

•Designed for use with 5/16" 150 Ksi tubing only, Vee stem

tip (Shutoff) only

Needle Valve, Yoke Style - Y Series 50,000 PSI

Parker Autoclave's Y Series yoke valves are a non-rotating rising stem design, working pressures to 50,000 psi (3447 bar). These yoke valves are extra heavy duty, plant grade instrument valves for industrial and severe service applications. Yoke valves feature low closing torque for ease of operation. The tubing size is 9/16” to 1”. Tubing connections utilize the Parker Autoclave cone and thread design. Standard high pressure needle valves with PTFE packing may be operated from 0°F (-17.8°C) to 450°F (232°C). High temperature packing is available for service 600°F (316°C). These high pressure needle valves have adjustable packing below the threads to eliminate the media from contacting the power threads, and causing galling during actuation.

Along with

their many features these valves provide dependable and trouble free service in

wide variety of applications.

Needle Valve, Diverter 20DV Series - 20,000 PSI

Parker Autoclave's 20DV Series diverter needle valves

are designed with a non-rotating rising stem valve, with working pressures to

20,000 psi (1379 bar). This diverter valve uses the Parker Autoclave tubing in

sizes ranging from 9/16"" to 1"". Diverter valves provide

the ability to direct incoming flow to one of two outlets. Flow is changed by rotating

the handle in or out causing a double-ended stem to block the flow path to the

outlet not needed.

Diverter valves eliminate the need for multiple valves

and the possibility of error in flow direction changes. The 20DV series uses

Parker Autoclave Engineers' medium pressure connection. This coned and threaded

connection provides a reliable bubble-tight seal for dependable performance in

a variety of applications.