Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

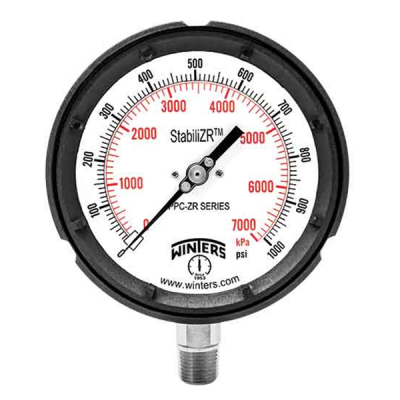

Pressure Gauges

Winters

Instruments, a leading manufacturer of pressure and temperature instruments,

provides a breadth of services related to industrial instrumentation. Winters

provide StabiliZR dampened movement gauges, which minimizes effects of

pulsation and vibration as effectively as liquid filled gauges. Winters boasts

multiple, fully equipped service centers staffed by skilled instrumentation

technicians. In addition, Winters can provide engineering expertise for complex

applications and large projects.

Range of Pressure Gauges in Winters Instruments:-

PFP Series Pressure Gauge

(Full SS)

Applications:

• Outdoor

and severe ambient and process conditions • Use where harmful vibration and

pulsation are present • Hydraulic equipment, oil field equipment, pumps,

compressors and process industries

Description & Features:

•

Stainless steel case & Socket

• SS316L

wetted parts

• Under

and overload stops (4” and 6”)

• Back,

bottom or panel mounted

• ASME

B40.100 compliant (EN837-1 available)

PFQ Series Pressure Gauges

(SS Case

with Brass Socket)

Applications:

• Ideal

for pumps, compressors, hydraulic presses, machinery, pneumatic equipment and

motors in harsh environments

• Use

where harmful vibration and pulsation are present

Description & Features:

• SS Case

& Brass Sockets

• Bronze

Bourdon Tube

• Crimp-on

bezel

• Brass

internals

• U-Clamps

and front flanges for panel mounting

• ASME

B40.100 compliant (EN837-1 available)

PEM Series Pressure Gauge

( Steel

Case with Brass connection)

Description & Features:

• Most

economical, all-purpose pressure gauge

• 1.5”

(40mm) to 4” (100mm) sizes

• Friction

bezel rings

• Black

steel case

• Brass

wetted parts

• ±3-2-3%

accuracy

PLP Series ( Low Pressure Measurement Gauge)

Applications:

• Suitable

for measuring gaseous media both corrosive and non-corrosive

• Used to

measure natural gas pressure as well as air fl ow indication and leak detection

• Vacuum

pumps, air compressors, air filters, gas burners, vacuum ovens, suction

regulators and respirators

Description & Features:

• Highly

accurate reading of low pressures

• Brass or

stainless steel wetted parts

• Ranges

from 15” H2 O/oz to 10 psi

•

Over-pressure protection on some models (OP)

• ASME B40.100 compliant • CRN registered • 5

year warranty

PN2 Series Pressure Gauge

(NACE

Pressure Gauges)

Applications:

• Sour gas

applications requiring gauges that meet NACE International Standards

Description & Features:

• Designed

for sour gas applications requiring NACE Standards MR0175-2002 (NACE Standards

MR0103-2003 available)

• Blow out

back plug

•

Laminated Safety Glass

• Under

and overload stops

• Wetted

parts meet hardness requirements

PPC Series (Phenolic Case, Solid Front, Blow out Back Pressure

Gauge)

Description & Features:

• Solid

phenolic front and polypropylene pressure relief back safety case

• Field

liquid-fillable (bottom connection only)

• ±0.5%

accuracy • Stainless steel full rotary movement for longer life

•

Micrometer adjustable pointer for ease in calibration

• Under

and overload stops • 316L stainless steel, brass, Monel® wetted parts •

Restricted orifice standard on dual scale (optional on single scale)

• ASME

B40.100 compliant • CRN registered • 5 year warranty

PSC Series (Safety Gauge – Solid Front)

Description & Features:

• Solid

front blowout back for the ultimate in gauge safety • Full rotary movement and

micrometer pointer for ease in calibration • Overload stop • Stainless steel

case, socket and internals • Safety glass lens • Restricted orifice standard

Applications:

• Used

where operator safety is a must • Outdoor and severe ambient and process

conditions • Use where harmful vibration and pulsation are present (with liquid

filling) • Oil and gas, petrochemical, mining and power installations

Winters

Instruments, a leading manufacturer of pressure and temperature instruments,

provides a breadth of services related to industrial instrumentation. Winters

provide StabiliZR dampened movement gauges, which minimizes effects of

pulsation and vibration as effectively as liquid filled gauges. Winters boasts

multiple, fully equipped service centers staffed by skilled instrumentation

technicians. In addition, Winters can provide engineering expertise for complex

applications and large projects.

Range of Pressure Gauges in Winters Instruments:-

PFP Series Pressure Gauge

(Full SS)

Applications:

• Outdoor

and severe ambient and process conditions • Use where harmful vibration and

pulsation are present • Hydraulic equipment, oil field equipment, pumps,

compressors and process industries

Description & Features:

•

Stainless steel case & Socket

• SS316L

wetted parts

• Under

and overload stops (4” and 6”)

• Back,

bottom or panel mounted

• ASME

B40.100 compliant (EN837-1 available)

PFQ Series Pressure Gauges

(SS Case

with Brass Socket)

Applications:

• Ideal

for pumps, compressors, hydraulic presses, machinery, pneumatic equipment and

motors in harsh environments

• Use

where harmful vibration and pulsation are present

Description & Features:

• SS Case

& Brass Sockets

• Bronze

Bourdon Tube

• Crimp-on

bezel

• Brass

internals

• U-Clamps

and front flanges for panel mounting

• ASME

B40.100 compliant (EN837-1 available)

PEM Series Pressure Gauge

( Steel

Case with Brass connection)

Description & Features:

• Most

economical, all-purpose pressure gauge

• 1.5”

(40mm) to 4” (100mm) sizes

• Friction

bezel rings

• Black

steel case

• Brass

wetted parts

• ±3-2-3%

accuracy

PLP Series ( Low Pressure Measurement Gauge)

Applications:

• Suitable

for measuring gaseous media both corrosive and non-corrosive

• Used to

measure natural gas pressure as well as air fl ow indication and leak detection

• Vacuum

pumps, air compressors, air filters, gas burners, vacuum ovens, suction

regulators and respirators

Description & Features:

• Highly

accurate reading of low pressures

• Brass or

stainless steel wetted parts

• Ranges

from 15” H2 O/oz to 10 psi

•

Over-pressure protection on some models (OP)

• ASME B40.100 compliant • CRN registered • 5

year warranty

PN2 Series Pressure Gauge

(NACE

Pressure Gauges)

Applications:

• Sour gas

applications requiring gauges that meet NACE International Standards

Description & Features:

• Designed

for sour gas applications requiring NACE Standards MR0175-2002 (NACE Standards

MR0103-2003 available)

• Blow out

back plug

•

Laminated Safety Glass

• Under

and overload stops

• Wetted

parts meet hardness requirements

PPC Series (Phenolic Case, Solid Front, Blow out Back Pressure

Gauge)

Description & Features:

• Solid

phenolic front and polypropylene pressure relief back safety case

• Field

liquid-fillable (bottom connection only)

• ±0.5%

accuracy • Stainless steel full rotary movement for longer life

•

Micrometer adjustable pointer for ease in calibration

• Under

and overload stops • 316L stainless steel, brass, Monel® wetted parts •

Restricted orifice standard on dual scale (optional on single scale)

• ASME

B40.100 compliant • CRN registered • 5 year warranty

PSC Series (Safety Gauge – Solid Front)

Description & Features:

• Solid

front blowout back for the ultimate in gauge safety • Full rotary movement and

micrometer pointer for ease in calibration • Overload stop • Stainless steel

case, socket and internals • Safety glass lens • Restricted orifice standard

Applications:

• Used

where operator safety is a must • Outdoor and severe ambient and process

conditions • Use where harmful vibration and pulsation are present (with liquid

filling) • Oil and gas, petrochemical, mining and power installations