Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Oil & Fuel condition monitoring products

- Product Code: Oil & Fuel condition monitoring products

Oil & Fuel Condition monitoring products

Parker

Kittiwake specialise in On-Line and On-Site solutions for condition monitoring

of production critical plant and machinery.

NEW – LCM30

The Parker

icountLCM30 is a next generation fluid system contamination monitoring offering

an under 2-minute test procedure.

DIGI

WATER TEST KIT

Parker

Kittiwake's water test kit range provides a complete set of economically priced

equipment, with a level of accuracy suited to routine analysis.

AVIATION FUEL CONTAMINATION MONITORING

Development work carried out by the

CMC engineers, in conjunction with Aviation, highlighted the need for an

alternative test method to determine the levels of dispersed contamination in

Jet fuel.

INLINE

PARTICLE MONITOR – ICOUNTPD

The Parker iCountPD is a highly

compact, permanently mounted laser detection particle monitor that enables

continuous monitoring of contamination levels in hydraulic and fluid circuits.

Capable of communicating results in ISO4406 / AS4059 or NAS1638.

ICOUNTBS

PLUS - BOTTLE SAMPLER

The revolutionary icountBS is an

advanced, fully contained bottle sampling system that ensures fast, accurate

and repeatable detection of contamination in hydraulic oils and hydrocarbon

fuels.

Oil & Fuel Condition monitoring products

Parker

Kittiwake specialise in On-Line and On-Site solutions for condition monitoring

of production critical plant and machinery.

NEW – LCM30

The Parker

icountLCM30 is a next generation fluid system contamination monitoring offering

an under 2-minute test procedure.

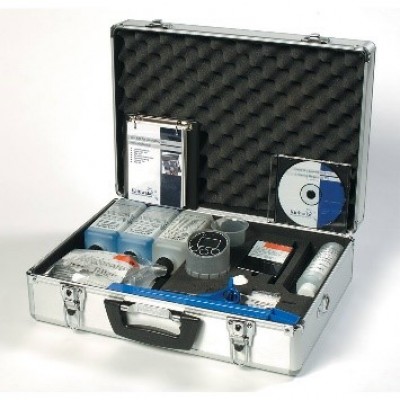

DIGI

WATER TEST KIT

Parker

Kittiwake's water test kit range provides a complete set of economically priced

equipment, with a level of accuracy suited to routine analysis.

AVIATION FUEL CONTAMINATION MONITORING

Development work carried out by the

CMC engineers, in conjunction with Aviation, highlighted the need for an

alternative test method to determine the levels of dispersed contamination in

Jet fuel.

INLINE

PARTICLE MONITOR – ICOUNTPD

The Parker iCountPD is a highly

compact, permanently mounted laser detection particle monitor that enables

continuous monitoring of contamination levels in hydraulic and fluid circuits.

Capable of communicating results in ISO4406 / AS4059 or NAS1638.

ICOUNTBS

PLUS - BOTTLE SAMPLER

The revolutionary icountBS is an

advanced, fully contained bottle sampling system that ensures fast, accurate

and repeatable detection of contamination in hydraulic oils and hydrocarbon

fuels.