Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

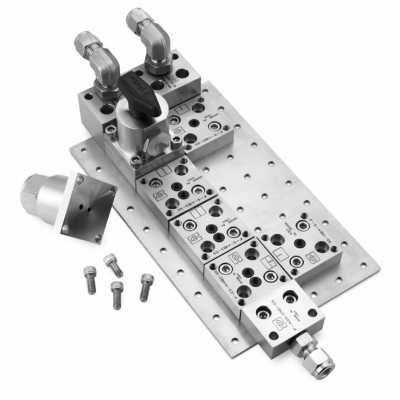

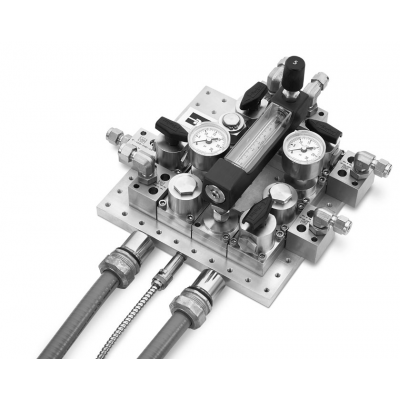

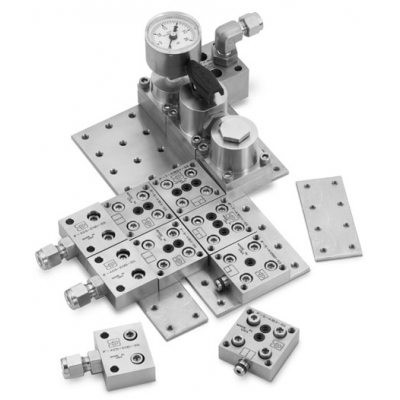

Sample conditioning system-Intra Flow

Sample Conditioning System, IntraFlow Series

Parker’s IntraFlow modular fitting and valve system was

developed specifically for analytical, lab and other complex general purpose

instrumentation flow control systems. These compact systems meet ISA/ANSI

SP76.00.02 requirements.

Product Overview

Parker’s

IntraFlow™ modular system has been developed specifically for analytical, lab

and other complex general purpose instrumentation flow control systems.

ISA/ANSI SP76.00.02 compliant, Parker IntraFlow™ fittings and valves provide

maximum flexibility with minimal space requirements. One of the unique features

is that all flow paths, regardless of direction, are maintained on a single

plane within the system as there are no lower level manifold blocks required.

The

compact, modular design provides contiguous fitting flow paths that are

intra-connected with slip fit pressure connectors, while a threaded pegboard

provides connection force and rigidity when fittings are mounted with cap

screws. System assembly couldn't be simpler. All you will need is a 5/32"

hex head wrench to build with Parker IntraFlow™.

Contact

your local Parker Instrumentation Distributor or the Factory for a complete

system design.

Markets:

•

Petrochemical

•

Refineries

•

Power Generation

•

Research

Features/Benefits:

•

System size is reduced as much as 75% compared with conventionally plumbed

systems, drastically reducing panel

space, internal volume and purge times

•

Compliant with ISA/ANSI SP76.00.02 open architecture standards

•

Complex system assembly was never easier! No tube benders or cutters required,

and no welding. All that's needed to

assemble is a 5/32” hex head wrench!

•

Every component on your Parker IntraFlow™ system can be reused when upgrading

with emerging NeSSI Generation 2 & 3 technologies

•

All flow paths are on the same plane: Parker IntraFlow™ eliminates lower level

manifolds to minimize system weight and leak potentials

•

Whether mounting a fitting to the standard 1/8" pegboard or a valve to the

fitting, the same 10-32 x 1/2" SHCS is the only screw required

Applications:

•

Process Analyzers

•

Stream Switching Systems

•

Analytical Equipment

•

Integrators

Tech Specifications

Performance

Characteristics

|

Connection Type |

NPT, SAE, Two Ferrule Compression Tube Fitting, Single Ferrule

Compression Tube Fitting |

|

Maximum Inlet Pressure Rating |

4000 psi 275 bar |

|

Maximum Operating Pressure |

500 psi 34 barg |

|

Function |

Optional |

|

Flow Control |

Included in system design when requested |

|

Industry Application |

Analyser Sample Conditioning |

|

Specifications Met |

ANSI/ISA 76.00.02, NeSSI |

|

Materials of Construction |

316 Stainless Steel |

|

Maximum Operating Temperature |

204 °C 400 °F |

|

Minimum Operating Temperature |

-57 °C -70 °F |

|

Mounting Type |

Surface Mount |

|

Application |

Sample Conditioning Systems |

|

Repairable |

Yes |

Sample Conditioning System, IntraFlow Series

Parker’s IntraFlow modular fitting and valve system was

developed specifically for analytical, lab and other complex general purpose

instrumentation flow control systems. These compact systems meet ISA/ANSI

SP76.00.02 requirements.

Product Overview

Parker’s

IntraFlow™ modular system has been developed specifically for analytical, lab

and other complex general purpose instrumentation flow control systems.

ISA/ANSI SP76.00.02 compliant, Parker IntraFlow™ fittings and valves provide

maximum flexibility with minimal space requirements. One of the unique features

is that all flow paths, regardless of direction, are maintained on a single

plane within the system as there are no lower level manifold blocks required.

The

compact, modular design provides contiguous fitting flow paths that are

intra-connected with slip fit pressure connectors, while a threaded pegboard

provides connection force and rigidity when fittings are mounted with cap

screws. System assembly couldn't be simpler. All you will need is a 5/32"

hex head wrench to build with Parker IntraFlow™.

Contact

your local Parker Instrumentation Distributor or the Factory for a complete

system design.

Markets:

•

Petrochemical

•

Refineries

•

Power Generation

•

Research

Features/Benefits:

•

System size is reduced as much as 75% compared with conventionally plumbed

systems, drastically reducing panel

space, internal volume and purge times

•

Compliant with ISA/ANSI SP76.00.02 open architecture standards

•

Complex system assembly was never easier! No tube benders or cutters required,

and no welding. All that's needed to

assemble is a 5/32” hex head wrench!

•

Every component on your Parker IntraFlow™ system can be reused when upgrading

with emerging NeSSI Generation 2 & 3 technologies

•

All flow paths are on the same plane: Parker IntraFlow™ eliminates lower level

manifolds to minimize system weight and leak potentials

•

Whether mounting a fitting to the standard 1/8" pegboard or a valve to the

fitting, the same 10-32 x 1/2" SHCS is the only screw required

Applications:

•

Process Analyzers

•

Stream Switching Systems

•

Analytical Equipment

•

Integrators

Tech Specifications

Performance

Characteristics

|

Connection Type |

NPT, SAE, Two Ferrule Compression Tube Fitting, Single Ferrule

Compression Tube Fitting |

|

Maximum Inlet Pressure Rating |

4000 psi 275 bar |

|

Maximum Operating Pressure |

500 psi 34 barg |

|

Function |

Optional |

|

Flow Control |

Included in system design when requested |

|

Industry Application |

Analyser Sample Conditioning |

|

Specifications Met |

ANSI/ISA 76.00.02, NeSSI |

|

Materials of Construction |

316 Stainless Steel |

|

Maximum Operating Temperature |

204 °C 400 °F |

|

Minimum Operating Temperature |

-57 °C -70 °F |

|

Mounting Type |

Surface Mount |

|

Application |

Sample Conditioning Systems |

|

Repairable |

Yes |