Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

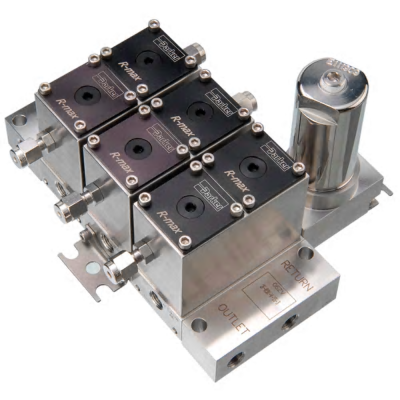

Stream Switching System, R-Max Gen-II

Stream Switching System, R-Max II Series

Parker's R-Max II is a multi-functional component system capable

of integrating both stream switching and filtering into one unique compact

assembly. These systems can easily be expanded to handle multiple streams “side

by side”.

The Parker Gen II R-max™ is a multi-functional

system capable of integrating both stream switching and filtering into one

unique compact assembly. The system is designed to control both gases and

liquids in analytical systems ranging from vacuum to 500 psig (34 bar) while

requiring only 65 psig (5 bar) actuat¬ing air pressure. The system was

engineered with a focus on improved product reliability and reduced cost of ownership.

The Parker Gen II R-max™ Stream Switching System utilizes state-of-the-art

surface mount technology to reduce leak paths, internal volume, and dead

volume. With surface mounting, system components may be easily removed and

replaced without breaking process connections. In addition, the Parker Gen II

R-max™ system utilizes an internal self-purging outlet header to eliminate the

need for an additional outlet loop.

•

Petrochemical

•

Refineries

•

Power Generation

•

Research

•

Enhanced position indicator enables easy recognition of valve position for

maximum system safety.

•

Backward compatibility allows the enhanced features to be added to existing

units.

•

Surface mount technology enhances maximum system flexibility and enables the

user to add additional streams to a system without interrupting installed

units.

•

Low internal volume insures maximum system efficiency by reducing purge time

and expensive purge gas.

•

Modular valve design offers maximum serviceability for quick and easy in-system

repair and reduced downtime.

•

The Gen II R-max™ is available for ANSI/ISA-76.00.02 (NeSSI) mounting.

•

Skid Integrators

•

Process Analyzers

•

Stream Switching Systems

•

Analytical OEM Equipment

Tech Specifications

Performance

Characteristics

|

Fitting Connection Type |

1/8" NPT Female |

|

Options |

None |

|

Seat Material |

PCTFE |

|

Seal Material |

Buna-N Rubber, Highly Fluorinated Fluorocarbon Rubber,

Fluorocarbon Rubber |

|

Body Material |

316 Stainless Steel |

|

Number of Housings |

2 to 20 |

|

Connection Size |

10-32 Plug, No Fitting, 1/8" Plastic Tubing, 1/8"

ALOK, 1/8" CPI, 1/8" NPT Female, 1/8" Plastic Tubing/10-32

Plug, 10-31 Plug, 1/8" NPT Female/10-32 Plug |

Stream Switching System, R-Max II Series

Parker's R-Max II is a multi-functional component system capable

of integrating both stream switching and filtering into one unique compact

assembly. These systems can easily be expanded to handle multiple streams “side

by side”.

The Parker Gen II R-max™ is a multi-functional

system capable of integrating both stream switching and filtering into one

unique compact assembly. The system is designed to control both gases and

liquids in analytical systems ranging from vacuum to 500 psig (34 bar) while

requiring only 65 psig (5 bar) actuat¬ing air pressure. The system was

engineered with a focus on improved product reliability and reduced cost of ownership.

The Parker Gen II R-max™ Stream Switching System utilizes state-of-the-art

surface mount technology to reduce leak paths, internal volume, and dead

volume. With surface mounting, system components may be easily removed and

replaced without breaking process connections. In addition, the Parker Gen II

R-max™ system utilizes an internal self-purging outlet header to eliminate the

need for an additional outlet loop.

•

Petrochemical

•

Refineries

•

Power Generation

•

Research

•

Enhanced position indicator enables easy recognition of valve position for

maximum system safety.

•

Backward compatibility allows the enhanced features to be added to existing

units.

•

Surface mount technology enhances maximum system flexibility and enables the

user to add additional streams to a system without interrupting installed

units.

•

Low internal volume insures maximum system efficiency by reducing purge time

and expensive purge gas.

•

Modular valve design offers maximum serviceability for quick and easy in-system

repair and reduced downtime.

•

The Gen II R-max™ is available for ANSI/ISA-76.00.02 (NeSSI) mounting.

•

Skid Integrators

•

Process Analyzers

•

Stream Switching Systems

•

Analytical OEM Equipment

Tech Specifications

Performance

Characteristics

|

Fitting Connection Type |

1/8" NPT Female |

|

Options |

None |

|

Seat Material |

PCTFE |

|

Seal Material |

Buna-N Rubber, Highly Fluorinated Fluorocarbon Rubber,

Fluorocarbon Rubber |

|

Body Material |

316 Stainless Steel |

|

Number of Housings |

2 to 20 |

|

Connection Size |

10-32 Plug, No Fitting, 1/8" Plastic Tubing, 1/8"

ALOK, 1/8" CPI, 1/8" NPT Female, 1/8" Plastic Tubing/10-32

Plug, 10-31 Plug, 1/8" NPT Female/10-32 Plug |