Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with Welcome to Supertechnical!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

API 6D Trunion Mounted-Block & Bleed Valves

Trunnion Mount Ball Double Block and Bleed Valve (DBB)

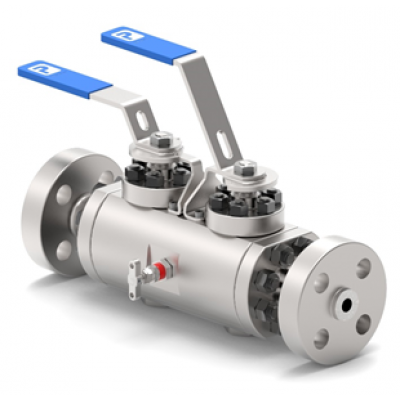

Pro-Bloc® FP Series

Floating Ball Double Block and Bleed

(DBB)

Parker’s Pro-Bloc® FP

series valve with floating ball design utilising both soft seats or metal seats

for bubble-tight sealing at a wide range of pressures and temperatures. The

valve has double block and bleed function and consists of two separate

isolating balls and one vent in a single unit. This three piece construction

offers space and weight saving benefits over the traditional method of using

three separate valves in process piping applications.

These valves are

supplied to the API 6D standards (excluding 15 mm bore).

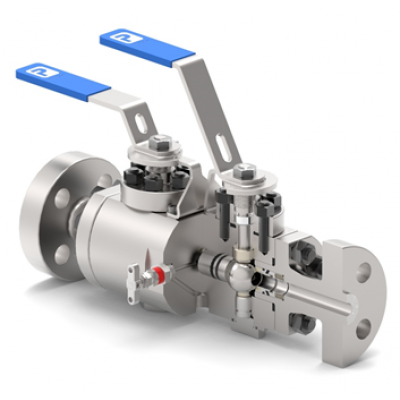

Pro-Bloc® TP Series

Trunnion Mount Ball

Double Block and Bleed (DBB)

Parker’s Pro-Bloc® TP

series trunnion mounted valve with a low operating torque is available with

either soft or metal seat options for bubble-tight sealing, spanning a wide

range of pressures and temperatures. The valve has double block and bleed

function and consists of two separate isolating balls and one vent in a single

unit. This three piece construction offers space and weight saving benefits

over the traditional method of using three separate valves in process piping

applications. These valves are supplied to the API 6D standards (excluding 15

mm bore)

Markets / Applications:

• Petrochemical

• Low temperature and LNG (tankers, terminals,

platforms, plants, air separation)

• Chemical

• Oil and Gas

Design Standards:

• Design: ASME B16.34, EEMUA 182

• Design pressure: ASME B16.34

• Body wall thickness: ASME B16.34, ASME VIII Div.

I

• Fire safe: API 6FA and API 607

Technical Specifications:

• Bore sizes - 15 mm, 25 mm, 38 mm, 50 mm

• Seat materials - TFM, PEEK, Metal

• Body materials - 316 Stainless Steel ASTM

A182-F316/ UNS S31600 Duplex ASTM

A182-F51 / UNS S31803 Super Duplex ASTM A182-F53/F55 Low Temp Carbon Steel ASTM

A350 LF2 Alloy 625 UNS N06625 Alloy 825 UNS N08825

• Valve configurations - Flange x screw & Flange x flange

• Max. Working Temperature - 360° C Min.

• Working Temperature - -196° C Max.

• Working Pressure - 6,250 PSI (431 bar)

Trunnion Mount Ball Double Block and Bleed Valve (DBB)

Pro-Bloc® FP Series

Floating Ball Double Block and Bleed

(DBB)

Parker’s Pro-Bloc® FP

series valve with floating ball design utilising both soft seats or metal seats

for bubble-tight sealing at a wide range of pressures and temperatures. The

valve has double block and bleed function and consists of two separate

isolating balls and one vent in a single unit. This three piece construction

offers space and weight saving benefits over the traditional method of using

three separate valves in process piping applications.

These valves are

supplied to the API 6D standards (excluding 15 mm bore).

Pro-Bloc® TP Series

Trunnion Mount Ball

Double Block and Bleed (DBB)

Parker’s Pro-Bloc® TP

series trunnion mounted valve with a low operating torque is available with

either soft or metal seat options for bubble-tight sealing, spanning a wide

range of pressures and temperatures. The valve has double block and bleed

function and consists of two separate isolating balls and one vent in a single

unit. This three piece construction offers space and weight saving benefits

over the traditional method of using three separate valves in process piping

applications. These valves are supplied to the API 6D standards (excluding 15

mm bore)

Markets / Applications:

• Petrochemical

• Low temperature and LNG (tankers, terminals,

platforms, plants, air separation)

• Chemical

• Oil and Gas

Design Standards:

• Design: ASME B16.34, EEMUA 182

• Design pressure: ASME B16.34

• Body wall thickness: ASME B16.34, ASME VIII Div.

I

• Fire safe: API 6FA and API 607

Technical Specifications:

• Bore sizes - 15 mm, 25 mm, 38 mm, 50 mm

• Seat materials - TFM, PEEK, Metal

• Body materials - 316 Stainless Steel ASTM

A182-F316/ UNS S31600 Duplex ASTM

A182-F51 / UNS S31803 Super Duplex ASTM A182-F53/F55 Low Temp Carbon Steel ASTM

A350 LF2 Alloy 625 UNS N06625 Alloy 825 UNS N08825

• Valve configurations - Flange x screw & Flange x flange

• Max. Working Temperature - 360° C Min.

• Working Temperature - -196° C Max.

• Working Pressure - 6,250 PSI (431 bar)